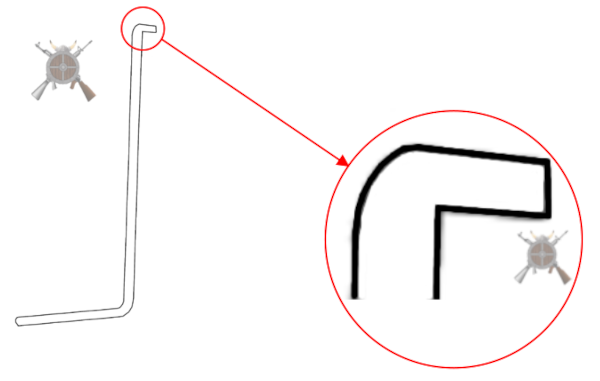

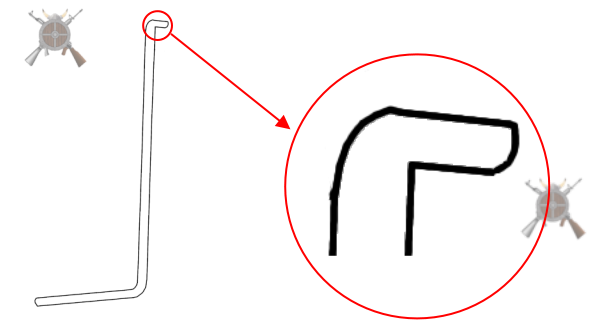

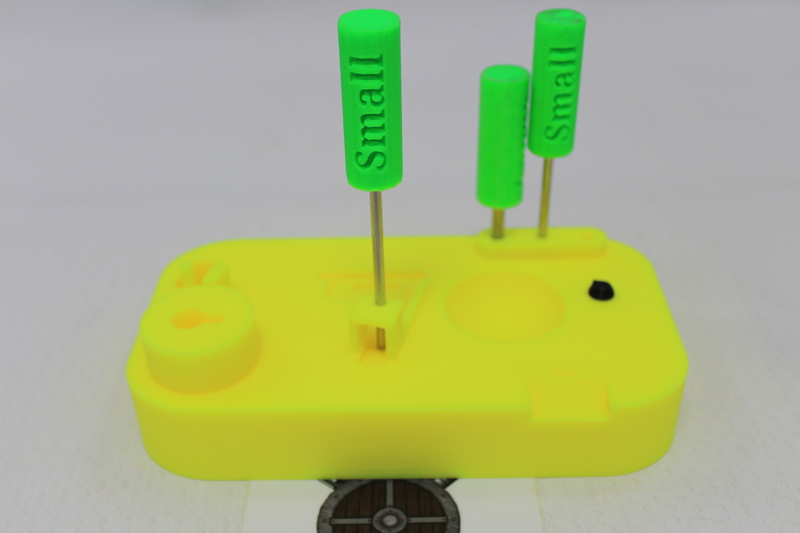

I want to give my Glock 44 as many rounds as my Glock 19. To do so I made some changes to the alex alex Glock 44 15 round magazine upgrade found in several places on the internet. I started with foxalex extension found on HERE on thingiverse. I added a slot for the magazine spring and side catches to help it hold better. My remix can be found HERE

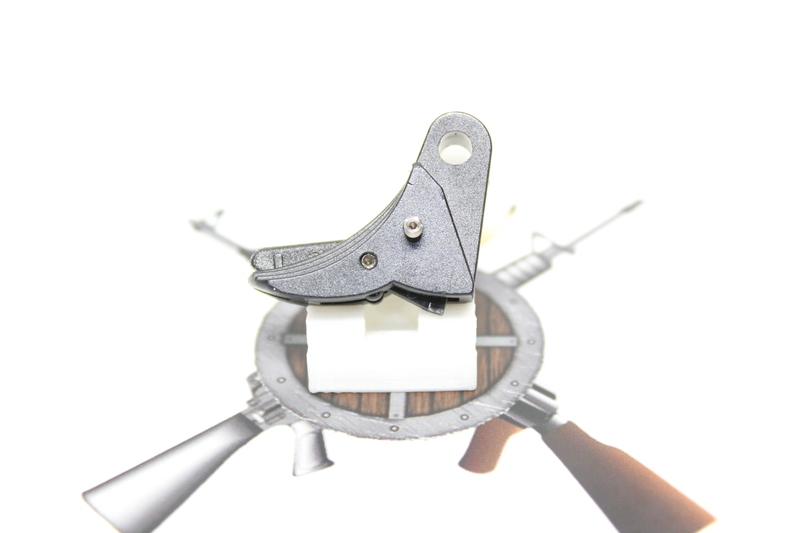

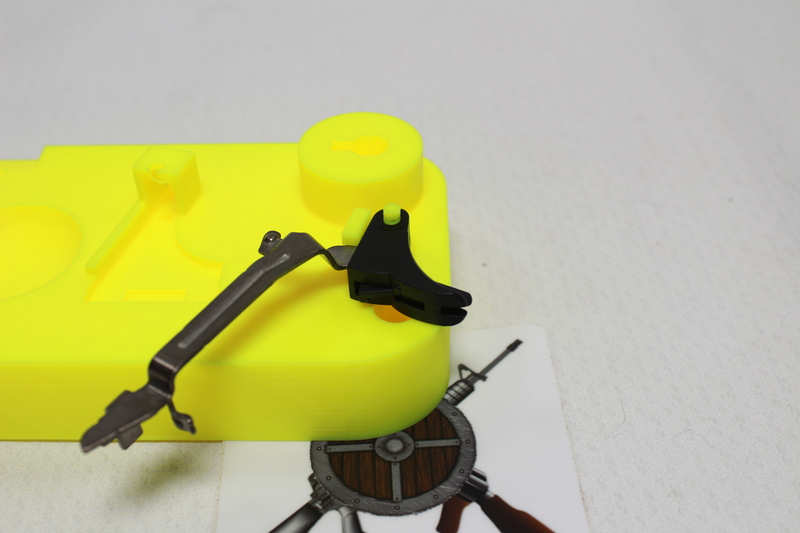

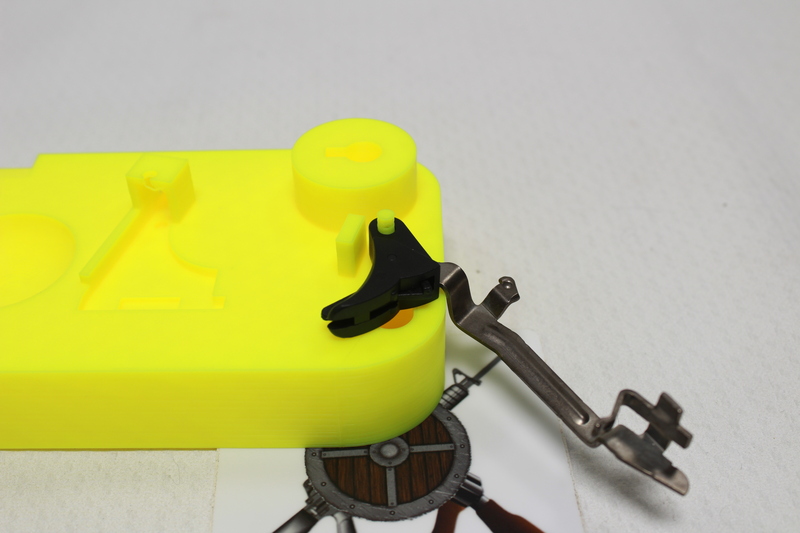

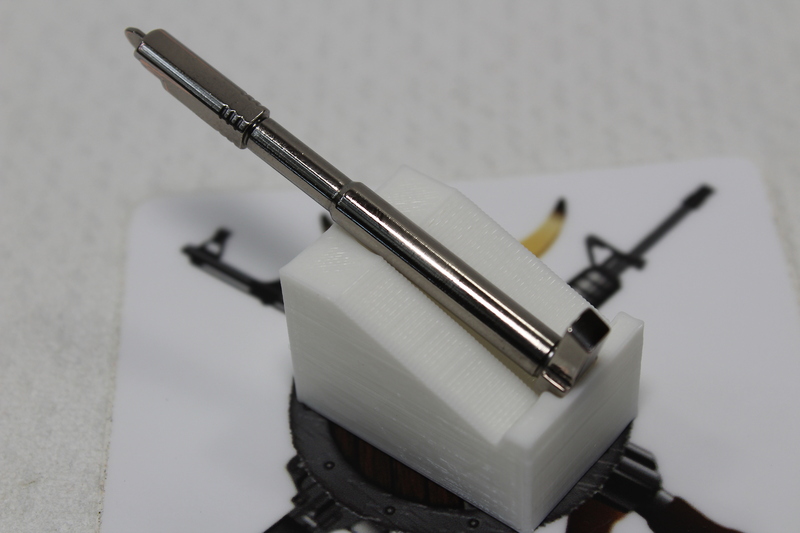

I used THIS follower. Make sure it is clean with no sharp edges and overhangs.

I attached it to a Walther PPQ 22 15+1 Replacement Magazine Spring. I did not want stretch my factory spring as suggested in some of the online articles. I like to keep all my factory parts as original as I can.

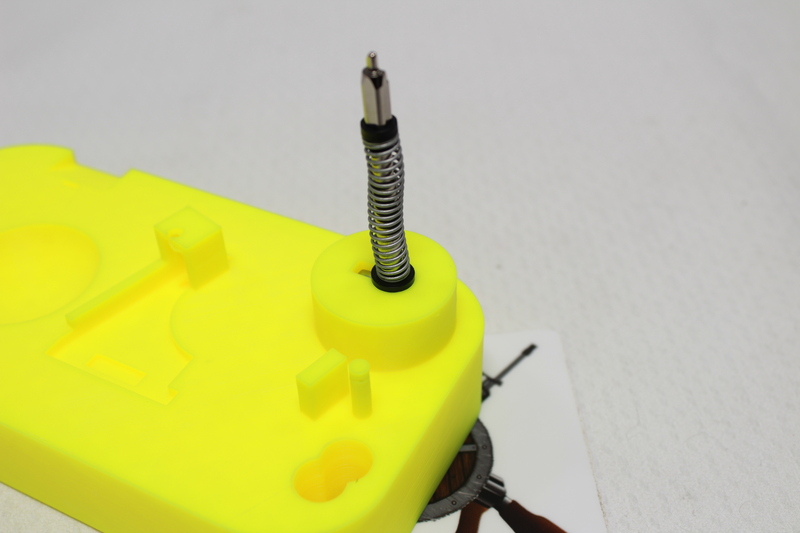

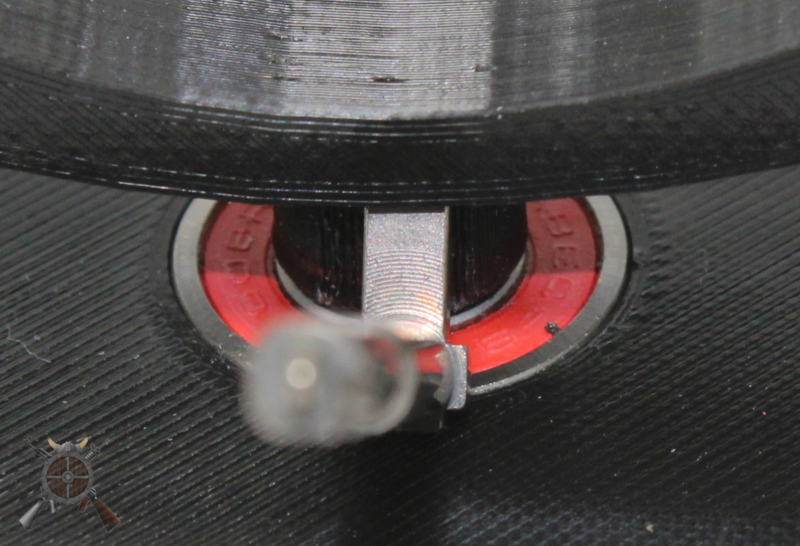

Then I slid the spring assembly into the magazine and made sure it slid without getting caught and hanging up on anything.

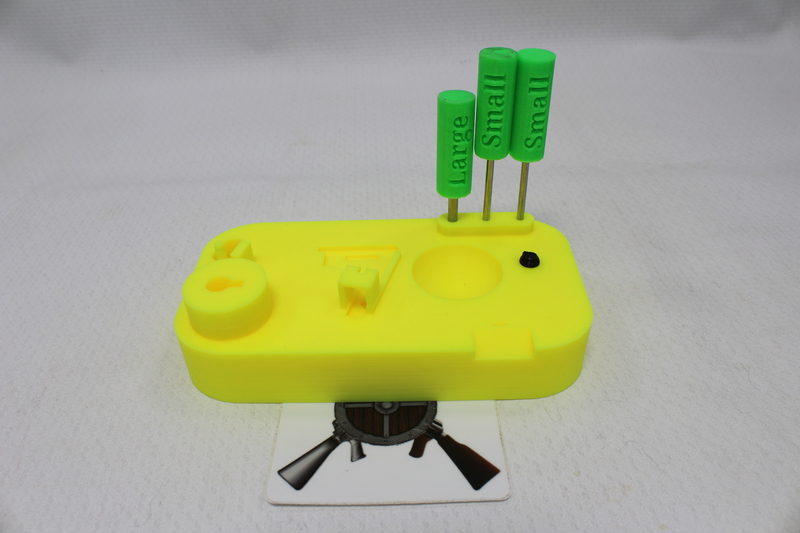

Slid the base back on:

For the final product:

I put around 100 rounds through it so far without issues. I will try and keep this post updated.