The above are average measurements. It is polymer, it moves so you will not get consistent measurements. They are mass produced and can vary in size between batch runs. The trigger I had at the time had the above measurements. Yours might vary. “A” was my distance to the center of the trigger bar slot.

We want to get the screw hole centered in front of the trigger bar slot (A) left to right and at the height of the front curve.

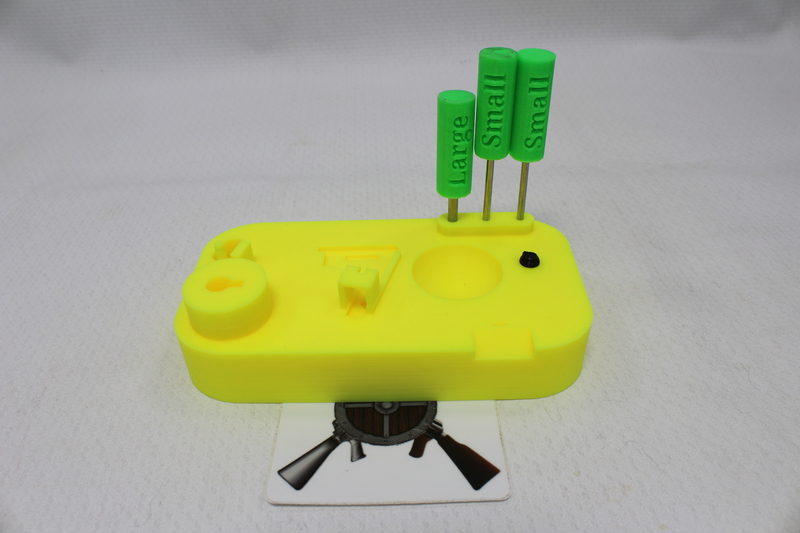

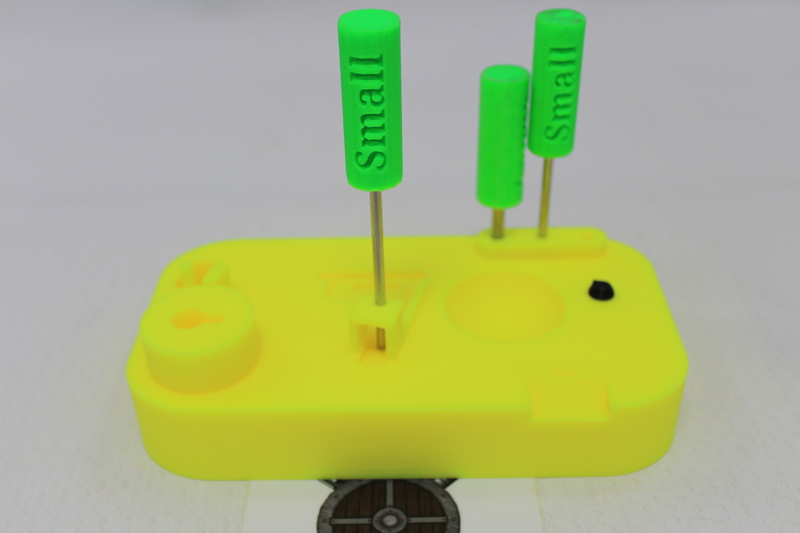

You are going to need Standard Trigger:

2 - 56 3/16 long stainless steel socket set screw 2 - 56 3/8 long stainless steel socket set screw for trigger bar .035 Allen Wrench #50 drill bit 2 - 56 tapered tap

You are going to need Performance Trigger:

2 - 56 3/16 long stainless steel socket set screw 2 - 56 3/8 long stainless steel socket set screw for trigger bar .035 Allen Wrench #50 drill bit 2 - 56 tapered tap

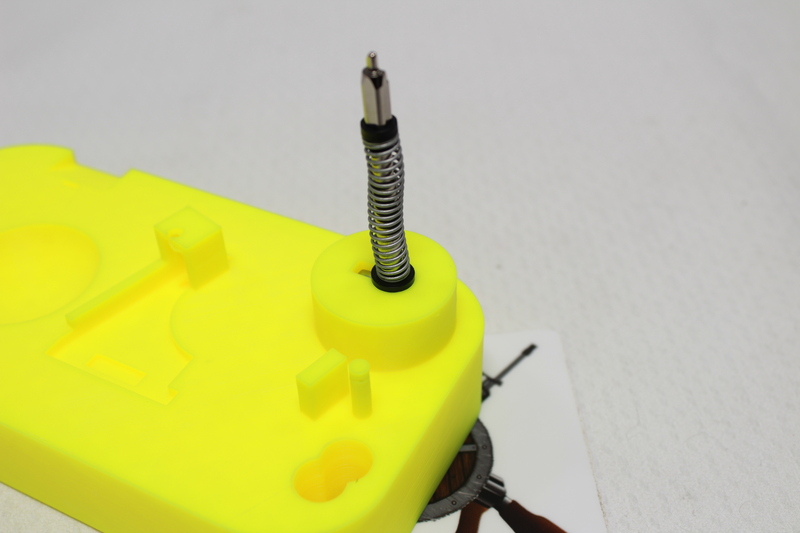

Using the #50 drill bit, drill a hole 9 mm down and center of the trigger bar slot. Make sure it is straight. I use my Dremel Drill press to do this. Slowly work the 2 – 56 tap through it.

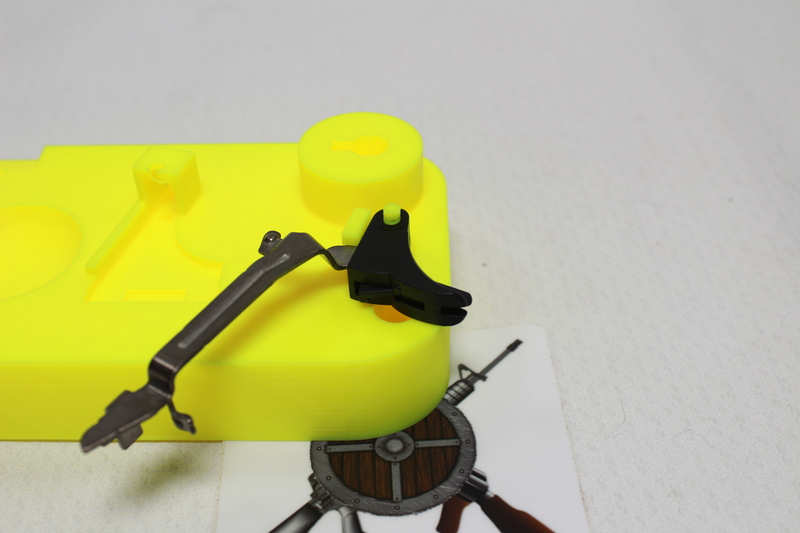

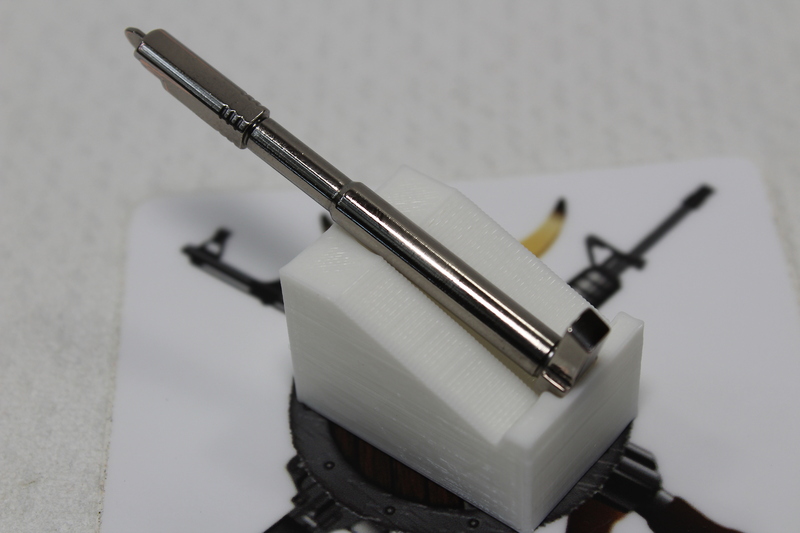

Front Shot:

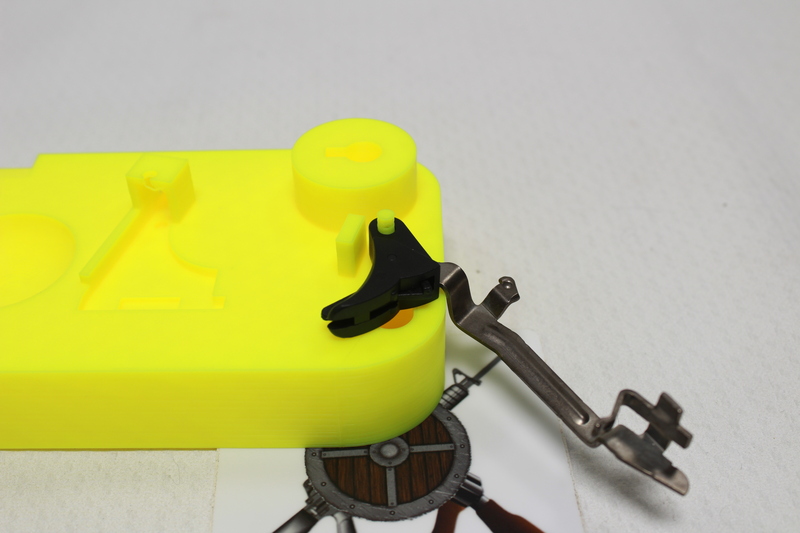

Looks pretty centered:

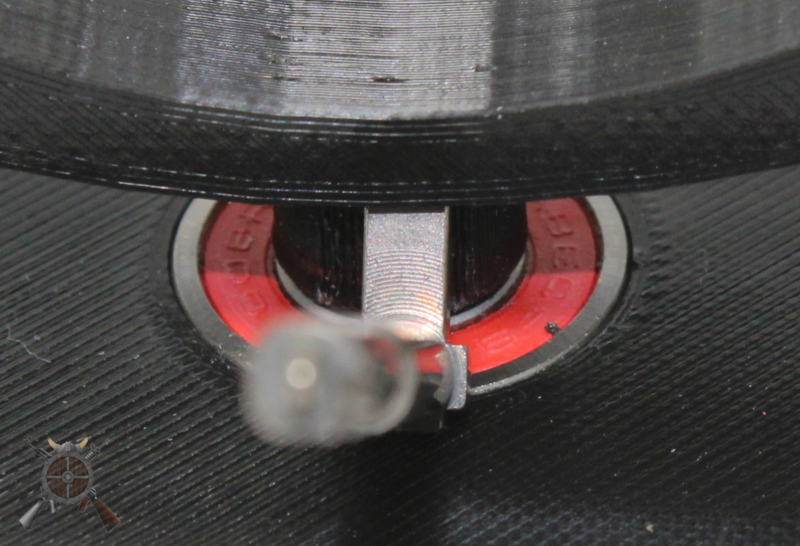

While I am at it, I drilled and tapped the safety and trigger bar holes with the above tools and threaded in 2 – 56 x 3/8” set screws

Once I am confident that everything is setup correctly, I will seal the deal with Loctite 425

I modified the safety on this trigger as well

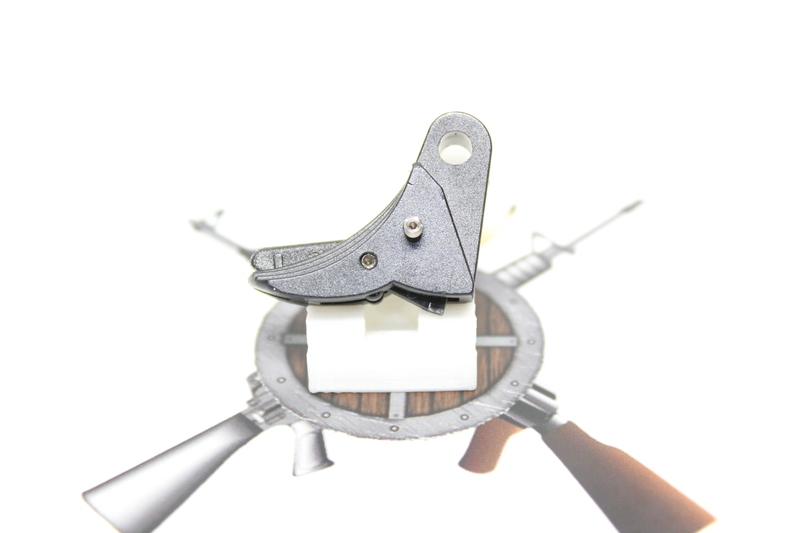

Here is what the trigger safety looks like unmodified:

There are 4 different cuts I am going to try.

Never cut off more than shown in the last example.

Here is the start of my testing:

Hit us up with comments or requests

All Documents posted on this site are for informational use only. If you make ANY modifications to your Weapons based on this site, you do at your own risk! If done incorrectly, you can render you weapon unsafe and / or unusable.

More HERE: https://viking-armory.com/?page_id=723