My Torque Values:

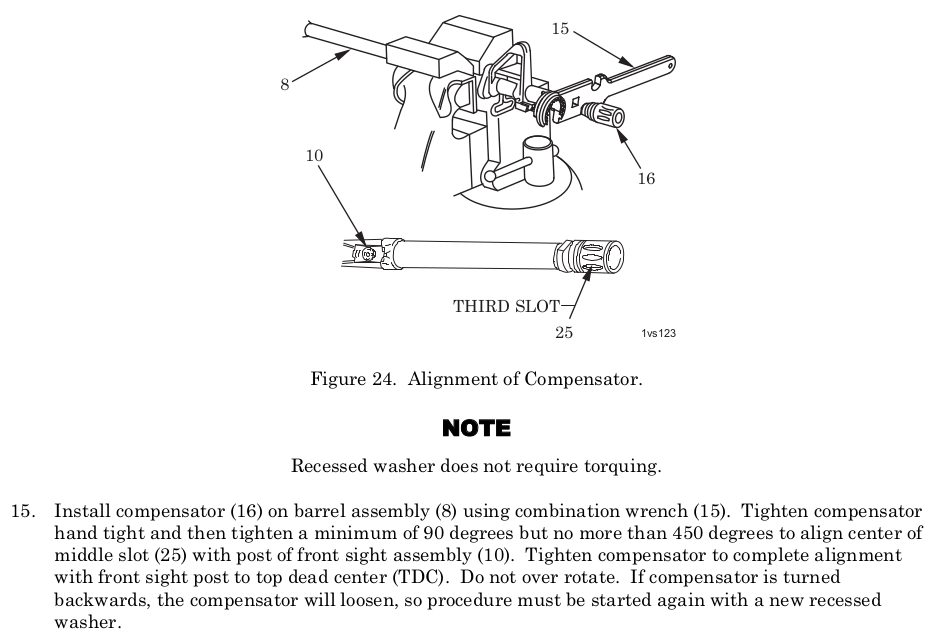

AR Compensator (Flash hider) No Torque, timing value with the procedure in the Army TM. Hand tight and then tighten a minimum of 90 degrees but no more than 450 degrees to timing. Don’t over tighten, don’t loosen.

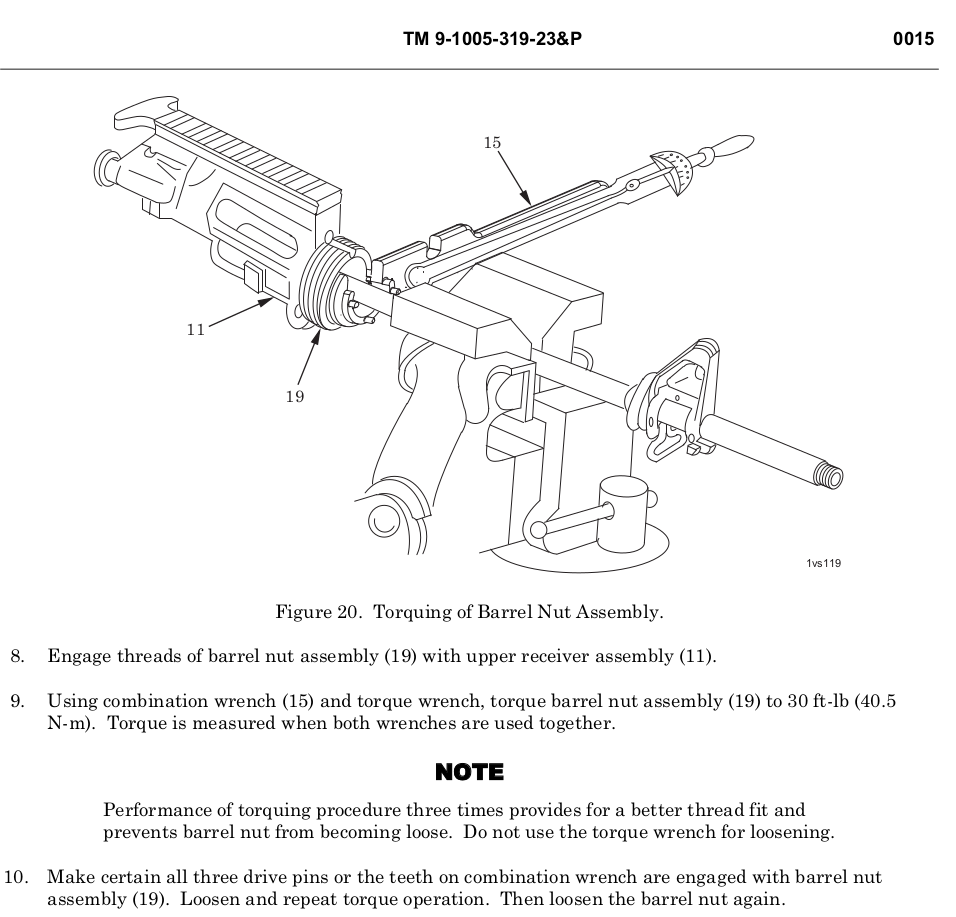

AR Barrel Nut 30 Ft. lbs. Minimum, not to exceed 80 Ft. Lbs. to align the next slot in the barrel nut. The 80 Ft. Lbs is not stated in the TM, but I don’t know how you would line up the gas tube, without going over 30 Ft. Lbs. Unless you use shims. I don’t think most folks will have any laying around. This torque spec is common across the community and internet.

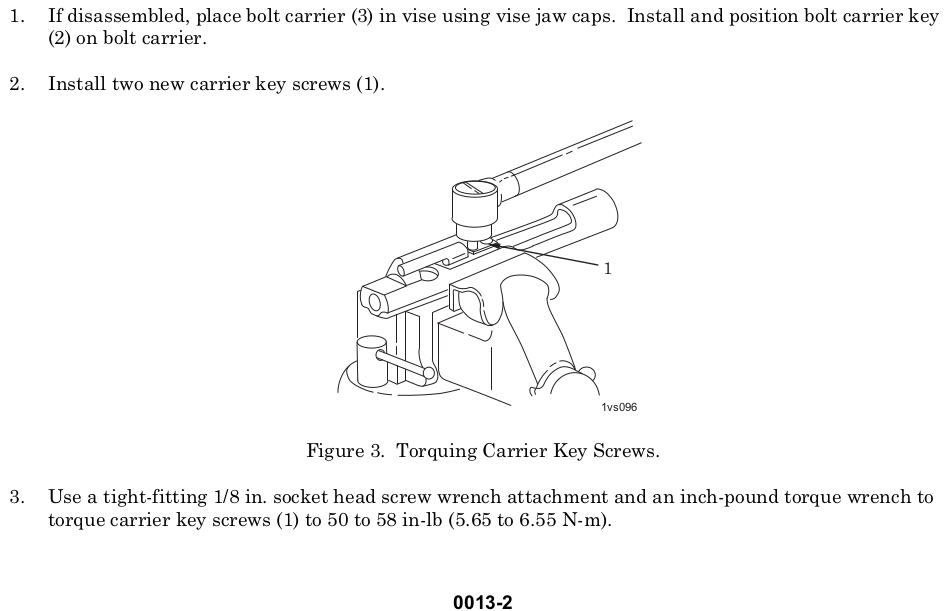

AR Carrier Key Screws 50-58 INCH pounds torque

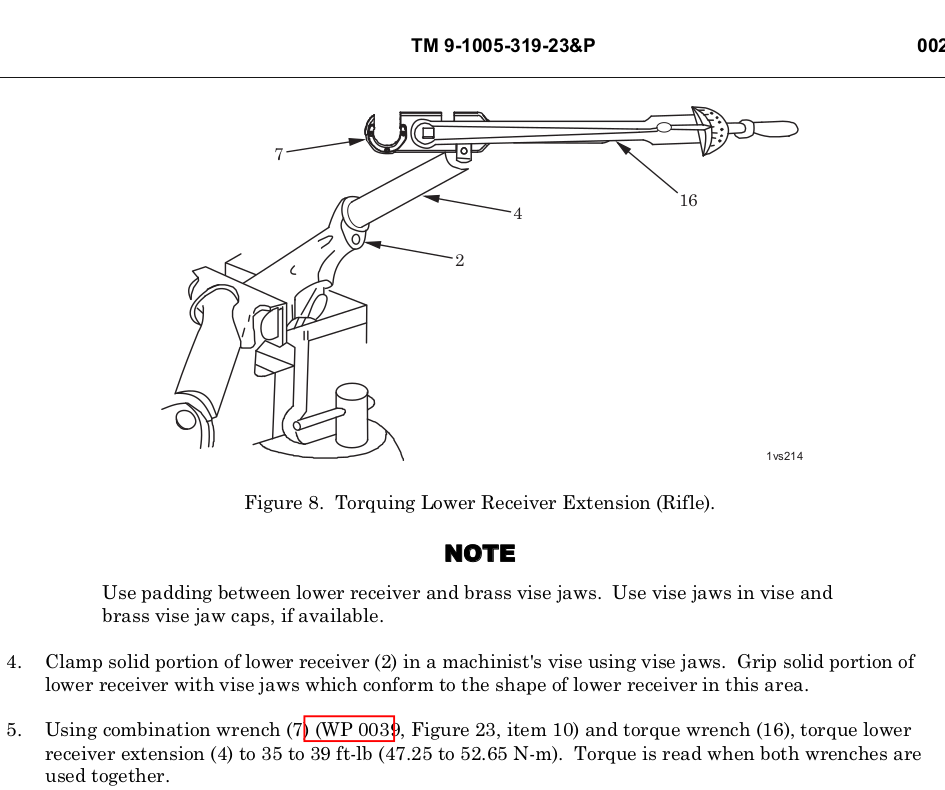

AR Lower Receiver Extension (Buffer Tube/Castle Nut) 40 Ft. lbs for both Rifle and Carbine.

M-LOK Accessories:

For attaching metal accessories to metal hand guards: 35 in/lbs

For attaching polymer or metal accessories to polymer hand guards: 15 in/lbs

For attaching polymer accessories to metal hand guards: 15 in/lbs

The installation torque values are not minimums, they are recommended limits. The nylon patch compound may slightly affect the torque reading if using an in/lb torque wrench.

Using a small hex wrench should prevent over-tightening. Remember that the recoil lugs are doing most of the work, and excessive torque on the nuts is not required

My Comments:

The rest of the items in the research below I could not find in the Army TM, manufacture website or in common reference. Until I can find it, I am going with ‘tight’ and the appropriate thread lockers. ‘Tight’ might be the values listed.

I am not saying that the info below is wrong or bad. I could not readily verify it. The above is what I will use, at the end of the day I am responsible for my decisions and you are responsible for yours.

########### RESEARCH ITEMS BELOW ###########

AR Compensator (Flash hider), 15-20 Ft. Lbs. Torque *1

AR Compensator (Flash hider) *3 (No Torque, timing value)

AR Handguard Screws, 20-30 inch pounds torque *1

AR Gas Block Set Screws, 25-30 inch pounds torque *1

AR Barrel Nut, 30 Ft. lbs. Minimum, not to exceed 80 Ft. Lbs. to align the next slot in the barrel nut. *1 *5

AR Barrel Nut, 30 Ft. lbs. *3 (I cant find the 80 Ft. Lbs. In the TM)

AR Carrier Key Screws, 50-58 INCH pounds torque *1 *2 *3

AR Grip Screw, 15-20 inch pounds torque *1

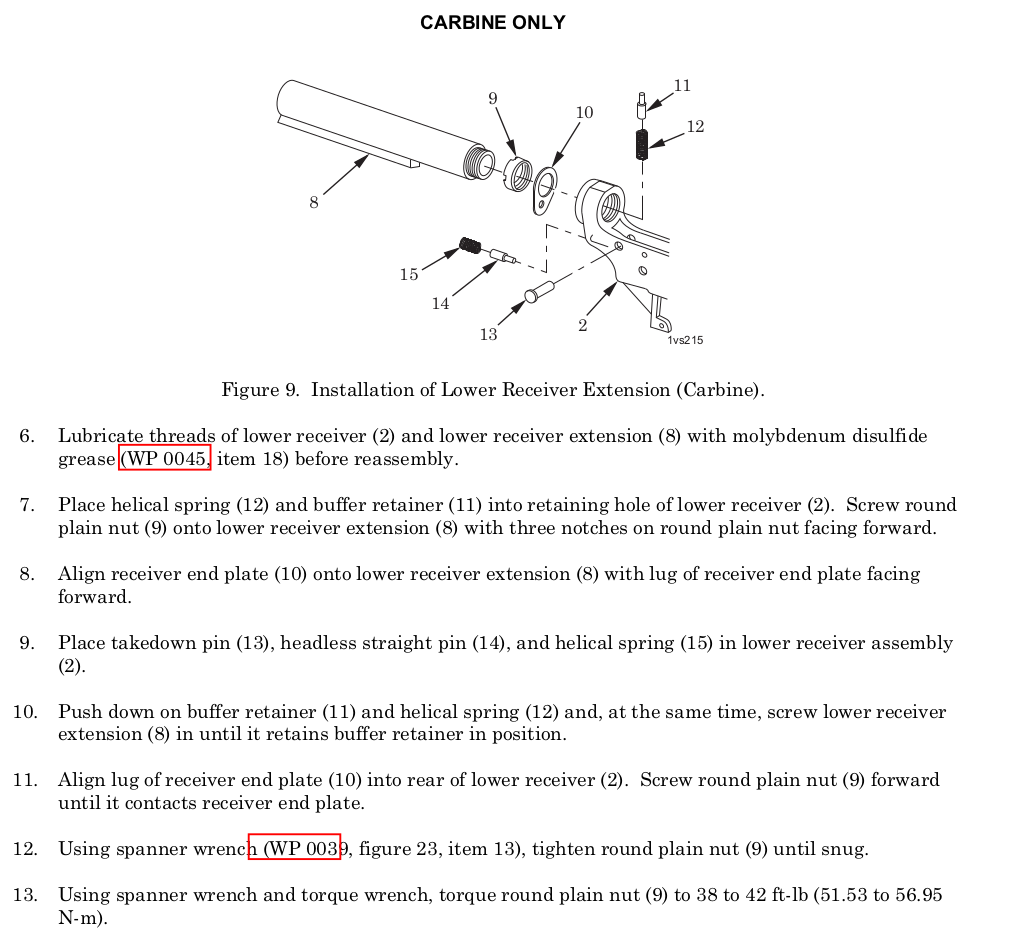

AR Lower Receiver Extension (Buffer Tube/Castle Nut)

Rifle: 35-39 Ft. Lbs. *1 *3

Carbine: 38-42 foot pounds *1 *3

M-LOK Accessories: *4

For attaching metal accessories to metal hand guards: 35 in/lbs

For attaching polymer or metal accessories to polymer hand guards: 15 in/lbs

For attaching polymer accessories to metal hand guards: 15 in/lbs

The installation torque values are not minimums, they are recommended limits. The nylon patch compound may slightly affect the torque reading if using an in/lb torque wrench.

Using a small hex wrench should prevent over-tightening. Remember that the recoil lugs are doing most of the work, and excessive torque on the nuts is not required

KeyMod Accessories: *1

Polymer to metal: 15 in-lbs

Polymer to polymer: 15 in-lbs

Metal to metal: 30 in-lbs

Picatinny Accessories: *1

Polymer to metal: 15 in-lbs

Polymer to polymer: 15 in-lbs

Metal to metal: 35-60 in-lbs

Ref:

*1 https://www.youtube.com/watch?v=Ah6WISs6IfY

*2 https://www.youtube.com/c/InstructorChad

*3 ARMY TM 9-1005-319-23&P Nov 2008

*4 https://www.dropbox.com/s/jrf9nwxnizjy6ql/M-LOK_Tips.pdf?dl=0 (Magpul MLOC instructions)

*5 https://www.youtube.com/watch?v=tcMqwofYTn0 (Brownells)

Hit us up with comments or questions

All Documents posted on this site are for informational use only. If you make ANY modifications to your Weapons based on this site, you do at your own risk! If done incorrectly, you can render you weapon unsafe and / or unusable.

More HERE: https://viking-armory.com/?page_id=723