After I made the plugs for the Firing Pin Protrusion Gauge Holder for iGaging Depth Gauge Digital Electronic Indicator, I realized 2 things.

1. I needed to sand down the plug just a bit so it would fit into the hole to get a negative reading.

2. I still had a hard time holding the bolt in a consistent manner. So I came up with the iGauge Firing Pin Protrusion Tool:

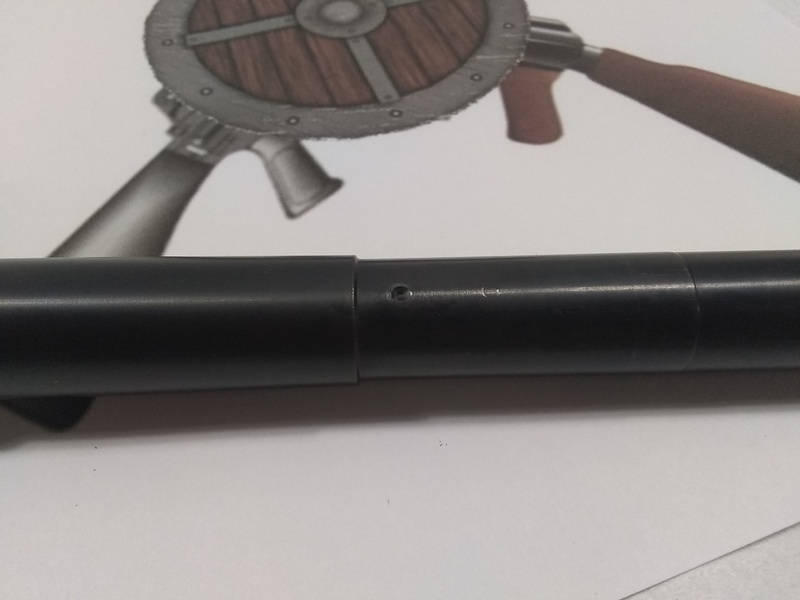

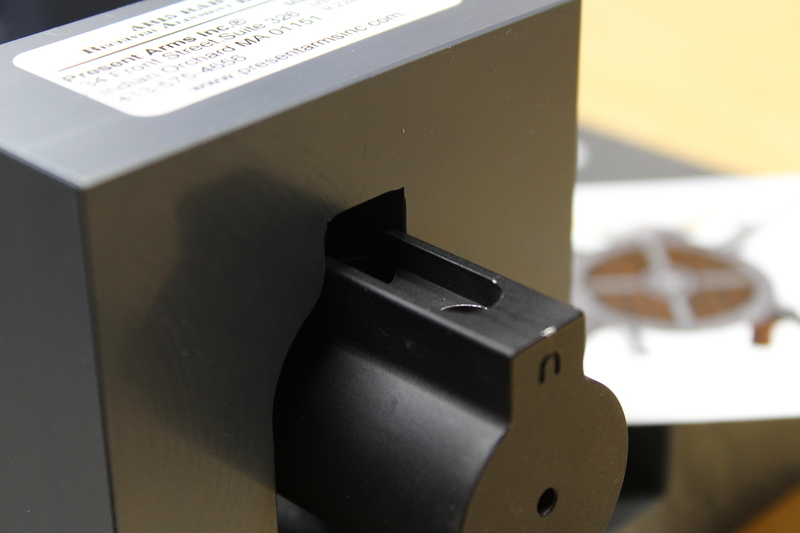

Naked:

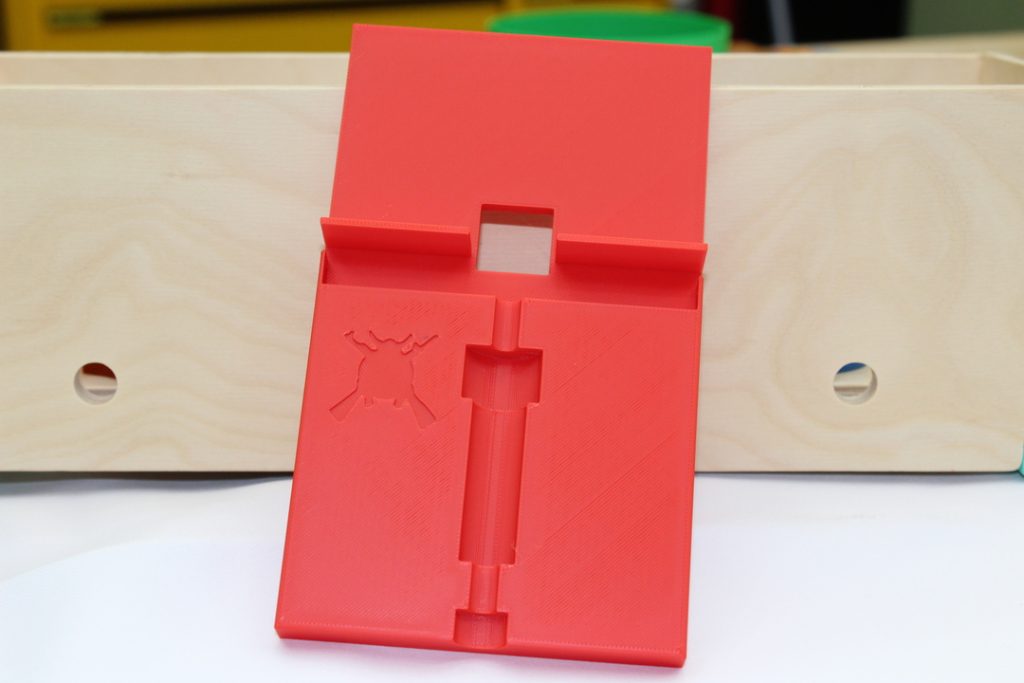

Dressed:

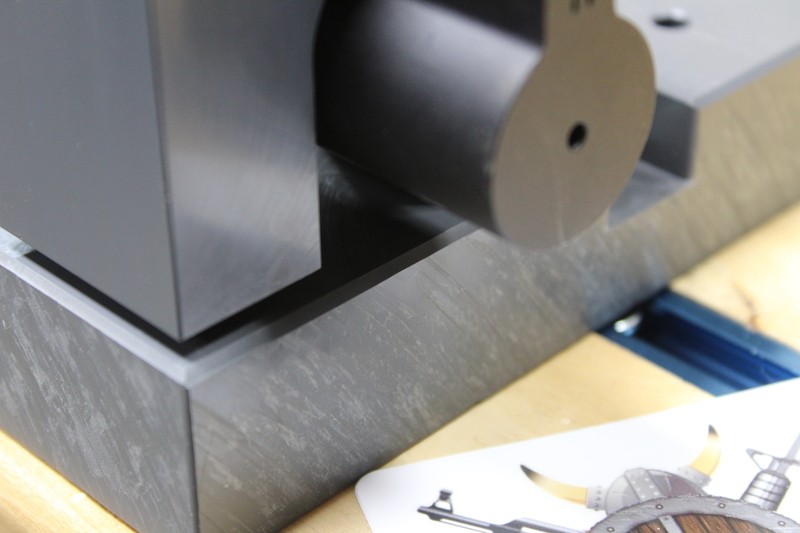

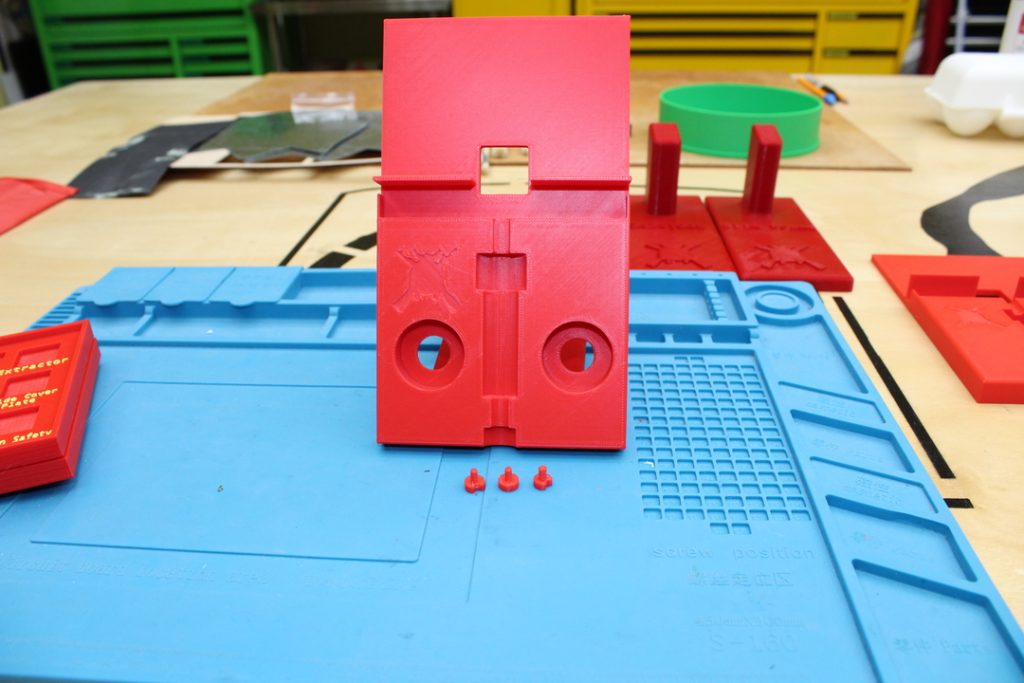

Then I added spots for boat tail NO-GO and Field Gage:

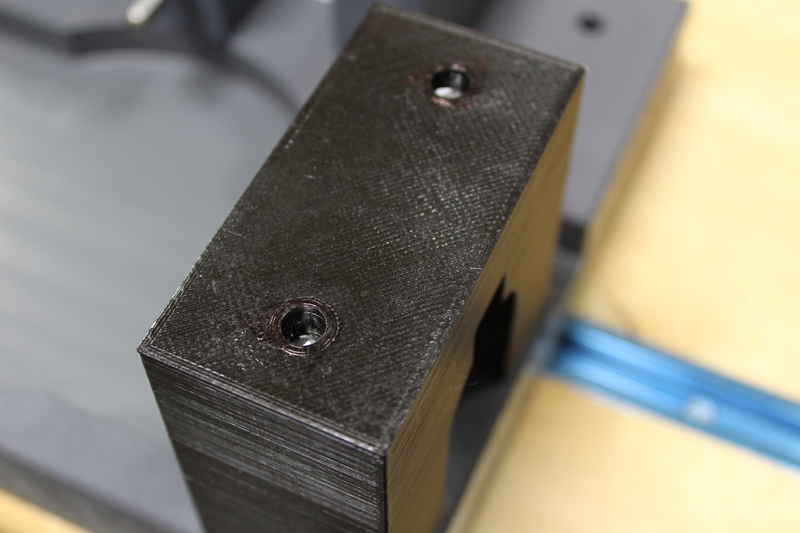

Naked:

Dressed:

Hit us up with comments or requestsAll Documents posted on this site are for informational use only. If you make ANY modifications to your Weapons based on this site, you do at your own risk! If done incorrectly, you can render you weapon unsafe and / or unusable.

More HERE: https://viking-armory.com/?page_id=723